Cutting-edge Eco-Tech Solutions

04

Bio Remediation of Waste Leachate

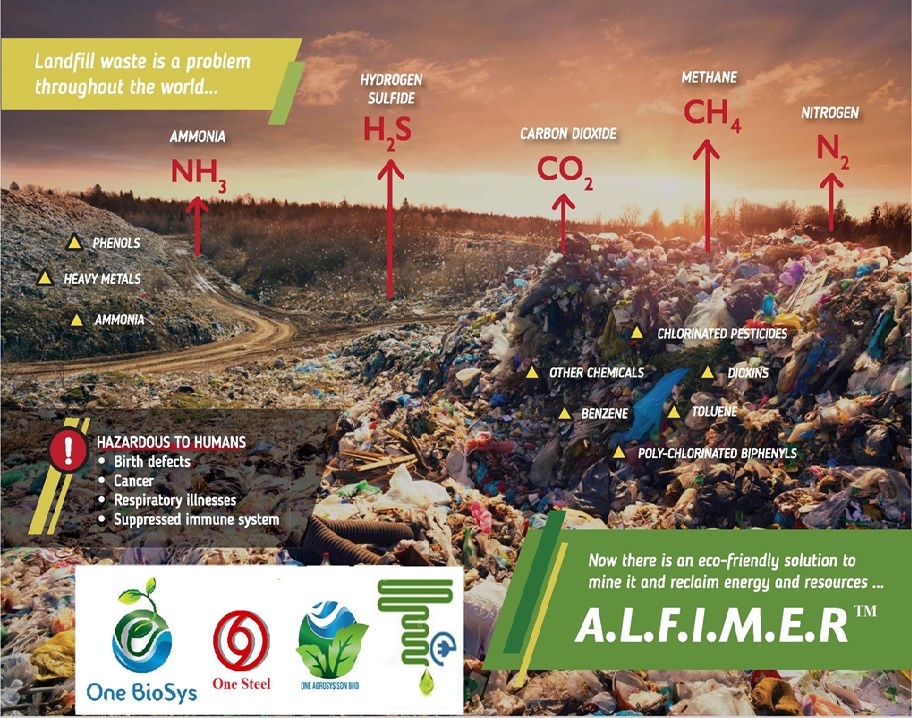

Bioremediation of waste leachate involves the use of living organisms or biological processes to remove pollutants and contaminants from leachate water. Leachate is a toxic liquid produced by the decomposition of waste in landfills, and can contain:

1. Organic pollutants (e.g. volatile organic compounds, VOCs)

2. Inorganic pollutants (e.g. heavy metals, ammonia)

3. Microorganisms (e.g. bacteria, viruses)

Bioremediation approaches for leachate include:

1. Aerobic treatment: Uses oxygen-loving microorganisms to break down organic pollutants – YaniSys™️

2. Anaerobic processing: Using microorganisms that thrive in an oxygen-free environment to degrade organic pollutants – Other Technologies Anaerobic Digestion [YaniSys™️ offers Methanogenic Enzymes to increase biogas volume]

3. Phytoremediation: Using plants to absorb and degrade pollutants – YaniSys™️

4. Microbial fuel cells: Using microorganisms to generate electricity while degrading pollutants – YaniSys™️

5. Bioaugmentation: Adding beneficial microorganisms to leachate to enhance biodegradation – YaniSys™️

6. Biostimulation: Adding nutrients or other substances to stimulate native microorganisms to degrade pollutants –

YaniSys™️ Benefits of bioremediation:

1. Effective removal of pollutants

2. Cost effective

3. Environmentally friendly

4. Can be used in situ (on-site) or ex situ (off-site)

5. Can be combined with other remediation techniques

Some examples of bioremediation in leachate include:

1. Using an aerobic reactor to remove VOCs and ammonia

2. Implement anaerobic digestion to produce biogas and reduce pollutants

3. Utilize wetland plants such as cattails or reeds to remove heavy metals

4. Adding microorganisms such as bacteria or fungi to degrade PAHs or PCBs It is important to remember that bioremediation may not always be effective or suitable for all types of pollutants or leachate conditions. Consult with an environmental scientist or bioremediation expert to determine the best approach for your specific situation.

Bioremediation Waste Leachate Inoculation – Foliar Nutrient Production Bioremediation waste leachate inoculation involves adding microorganisms to treated water to enhance the biodegradation process and ensure the water is safe for disposal or reuse. The purpose of inoculation is to:

1. Introduce beneficial microorganisms that can break down residual pollutants

2. Increases the degradation of organic materials

3. Improve overall water quality

Types of microorganisms used for inoculation:

1. Bacteria (e.g. Pseudomonas, Rhodococcus)

2. Fungi (eg white rot fungus, Trichoderma)

3. Yeast (e.g. Saccharomyces)

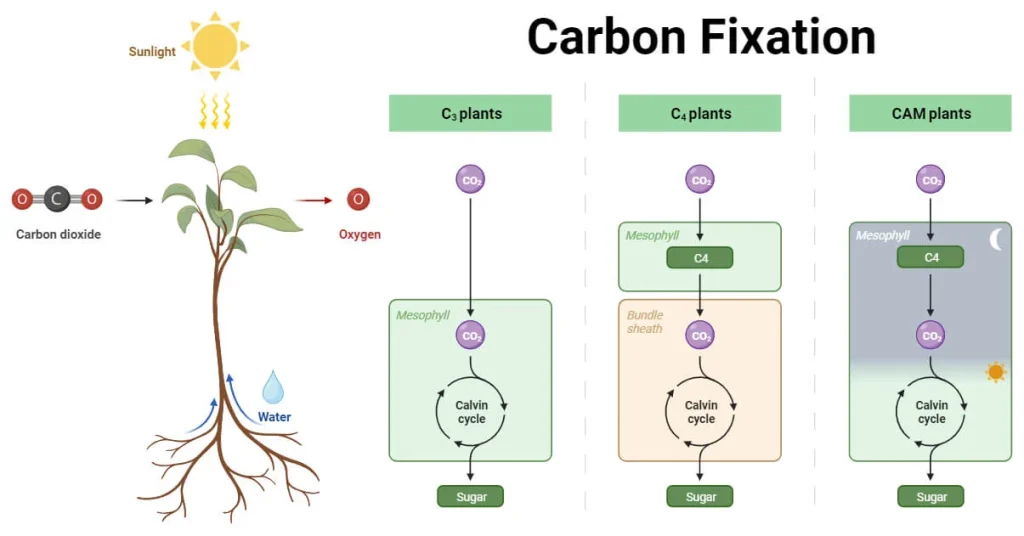

4. Introduction to the 1st, 2nd & 3rd

Carbon Fixing mechanism – YaniSys™️ Inoculation method:

1. Adding microorganisms directly to leachate

2. Using bioaugmentation products that contain beneficial microorganisms

3. Inoculate the biological reactor or processing system Factors to consider:

1. Type and concentration of microorganisms

2. Water temperature and pH

3. Availability of nutrients

4. The presence of toxic compounds or inhibitors

5. Monitoring and maintenance of the inoculation system

Benefits of inoculation:

1. Increased biodegradation of pollutants

2. Improved water quality

3. Reduce impact on the environment

4. Increased efficiency of the treatment process

5. Cost-effective and sustainable solution.

Remember to consult with experts in the fields of bioremediation and microbiology to determine the most appropriate inoculation strategy for your specific situation. *Palm Oil Mill Waste* Bioremediation of Palm Oil Mill Waste (POME) involves the use of living organisms or biological processes to remove pollutants and contaminants from POME. POME is a toxic liquid waste produced from palm oil processing, containing:

1. High levels of organic pollutants (e.g. fatty acids, oils)

2. Heavy metals (e.g. copper, zinc)

3. Nutrients (e.g. nitrogen, phosphorus)

4. Microorganisms (e.g. bacteria, viruses)

Bioremediation approaches for POME include:

1. Aerobic treatment: Uses oxygen-loving microorganisms to break down organic pollutants – YaniSys™️ Technologies

2. Anaerobic processing: Using microorganisms that thrive in an oxygen-free environment to degrade organic pollutants – Anaerobic Digestion System (YaniSys™️ Technology Methanogenic Enzymes to increase biogas volume)

3. Phytoremediation: Using plants to absorb and degrade pollutants – YaniSys™️ Technologies

4. Microbial fuel cells: Use microorganisms to generate electricity while degrading pollutants – Pyrolysis Systems

5. Bioaugmentation: Adding beneficial microorganisms to POME to enhance biodegradation – YaniSys™️ Technologies

6. Biostimulation: Adding nutrients or other substances to stimulate native microorganisms to degrade pollutants – YaniSys™️ Technologies Benefits of bioremediation:

1. Effective removal of pollutants

2. Cost effective

3. Environmentally friendly

4. Can be used in situ (on-site) or ex situ (off-site)

5. Can be combined with other remediation techniques Some examples of bioremediation of POME include:

1. Using an aerobic reactor to remove fatty acids and oils

2. Implement anaerobic digestion to produce biogas and reduce pollutants

3. Utilize wetland plants such as cattails or reeds to remove heavy metals

4. Adding microorganisms such as bacteria or fungi to degrade organic pollutants It is important to remember that bioremediation may not always be effective or suitable for all types of POME pollutants or conditions. Consult with an environmental scientist or bioremediation expert to determine the best approach for your specific situation.